Campbell Heights Fabrication Services

We are your one-stop shop for all your steel, aluminum and stainless fabrication, materials processing, assembly and finishing needs.

Below we list some—but not all—of the services we offer. You will find a brief description on this page, and then a link to further information about each of these topics.

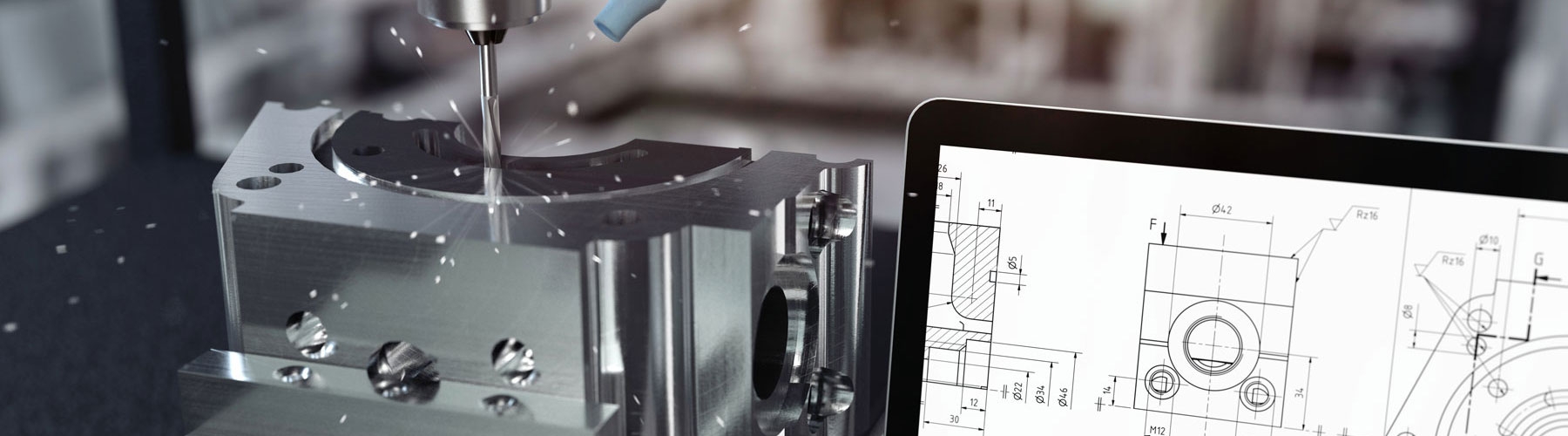

Fabrication

For us, fabrication means that we can manufacture most of our client’s equipment, products or projects. From small products such as guards to large-scale industrial applications and projects like, silos, hoppers, conveyors, concentrators and turnkey concrete batch plants, we do it all. We are available to help you transform complex ideas and specifications into cost-efficient solutions.

Our experience, expertise, and thoroughly equipped Surrey facility allows us to work on and complete the most intricate complex jobs large or small. For further information, have a look at our Fabrication Page.

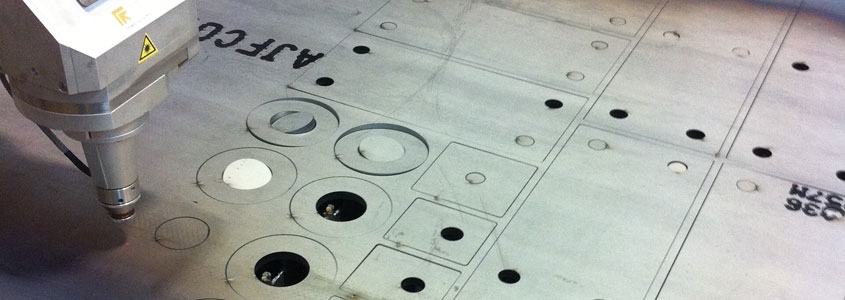

Laser Profiling

Laser profiling has revolutionized the steel industry lowering costs and improving lead times for all projects. Providing quality cut aluminum, stainless and mild steel parts with this cost-effective accurate process ensures a better end product.

We use our laser option when needed or required, for further information have a look at our Laser Profiling Page.

Forming

Steel, aluminum and stainless fabrication can include either profiling, forming or both. Forming is a fundamental process in fabrication; this is just one of many processes we offer our clients enabling us to complete projects from start to finish.

For further information, have a look at our Forming Page.

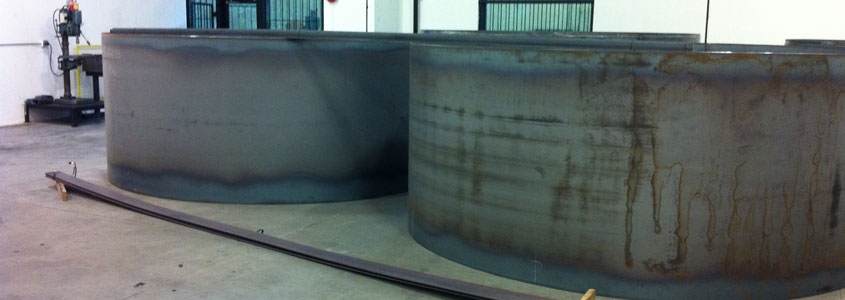

Rolling

Rolling is one of the processes available which enables us to fabricate cones, silos, tanks among other projects which require rolled components. If your project requires rolling, we can do it and be cost effective through this process.

For further information, have a look at our Rolling Page.

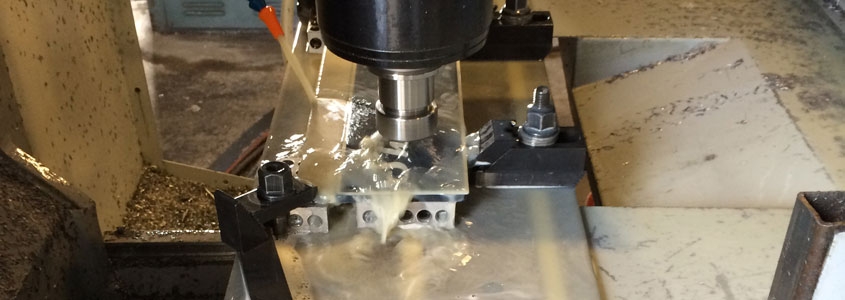

Light Machining

Light machining can mean many things from small repetitive parts requiring CNC work or small one-off components using a more hands on traditional manual lathe. Regardless of the equipment required we can handle all your light machining needs in our fully equipped shop.

For further information, have a look at our Light Machining Page.

Sandblasting and Painting

Sandblasting and painting are commonly needed within the steel fabrication industry, whether one is prepping a surface or finishing a newly fabricated product done at C H F or from a client, we have the means to get this done. With our facility and experience we will do our best to get it done in a timely cost-effective manner.

For further information, have a look at our Sandblasting and Painting Page.

High-Definition Plasma Cutting / flame cutting

Having this option alongside our Laser profiling capabilities allows us to profile both light and heavy materials when required. High-definition plasma cutting enables us to cleanly cut a variety of metals including steel, stainless steel, and aluminum. Our flame-cutting option increases our abilities when profiling much thicker steel when called upon.

The precision of plasma cutting also makes possible certain types of cost-effective and complex fabrication that would otherwise not be an option.

For further information, have a look at our High-Definition Plasma / Flame Cutting Page.

Waterjet Cutting

Waterjet Cutting is just another tool in our toolbox. We use our waterjet process for smooth lines, clean finishes, tight tolerances and this also eliminates all distortion of materials caused through plasma or laser profiling. Providing parts with tight tolerances also saves on machining, thus lowering your bottom line.

For further information, have a look at our Waterjet Cutting Page.